Plastic processing forums for extrusion information and advice and for other feed screw applications. Pipe Tubing Draw Down Ratio.

Extrusion Orientation The Good And The Bad Plastics Technology

Draw down ratio DDR and draw ratio balance DRB calculation need to be made to insure that correct product sizes are produced.

. Use generous internal and external radiuses on all corners. The neck-in is less if the melt elasticity is high. The rheology-related phenomena that may cause problems in extrusion coating are neck-in NI and draw-down DD.

The draw-down is the ability of the melt to be drawn to thin films without breaking. 1 That The Swell Ratio Increases With The Wall Shear Rate Gamasubw For Both Hdpe And Pvc. 9 Frombrazil IN USA Registered.

2006 1132 AM Hi Folks I currently extrude PE on a single screw extruder and use a Draw Down Ratio of 2 for tube covers and 339 for tube linersIDs range approx 63mm to 254mm and avg wall thickness is 2mm. The greater the DDR the more precise the final product diameter can be. Draw-down ratio DDR in a circular die such as a wire die is the ratio of the cross sectional areaof the die orificeopeningto the final extruded shape.

These calculations are available in standard extrusion texts. A 1 π 10 2 4 785 cm 2 and A 2 π 8 2 4 502 cm 2 ε ln R ln 156 044. The smallest possible radius is about 5 mm.

The neck-in is the reduction of the film width and may cause uncoated areas on the substrate. Without performing calculations for tip and dies sizes based on the final product dimensions and the consideration for the polymer being processed and. The holes in the breaker plate are normally 0318 cm 18 in to 0635 cm 14 in with a chamfer designed to give minimal obstruction to material flow.

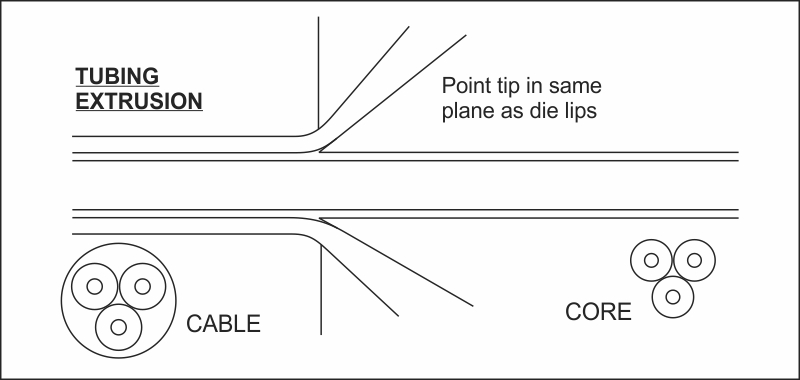

Table 1 Suggested Screw Design for Extrusion of Lubrizol TPUs. The first step is to find the extrusion ratio and the strain. The DDR is the ratio of the annular toolset exit area bushing ID area minus mandrel OD area divided by the final product area OD area minus ID area.

The hidden cost of tip and die defects extra inspection and troubleshooting Extrusion Analysis Calculators Use the BH DDRDRB Calculator to calculate the Draw Down Ratio and Draw Ratio Balance of your current tool set and the BH Tooling Calculator to determine the optimal Tip and Die sizes for a new product or application. R A 1 A 2 D 1 2 D 2 2 100 64 156 N o t e. Some basic guidelines in profile design minimize extrusion problems.

Extrusion line should be equipped with an air hood located close to the die to take off vapors evaporating from melt leaving the die. It is the extent to which the plastic has. Another guide for setting uniformity and best repeatable references is the draw ratio balanceDRB that aids in determining the minimum and maximum valuesthat can be used for different plastics.

Wall thickness ratio WTR die gap width divided by tubing wall thickness. Almost equal to DDR. Each resin has a characteristic range of DDR shown in.

Make interior walls thinner than exterior walls for cooling. DiesBushings Custom Dies Die Plates Face Seal Dies Floating Dies Adjustable Interchangeable Die-Plates Shouldered Dies. Ing for the perpendicular extrusion angle Kistler and Scriven11 calculated apparent contact angles dependent on both Reynolds number and the drawdown ratio VsV0.

Extrusion Analysis The calculators below allow you to calculate DDR draw Down Ratio and DBR Draw Balance Ratios for a given Tip Outer Diameter OD Die Outer Diameter OD and finished product OD and ID Inner Diameter. Specifically for viscous curtains they calculate the fol-lowing scaling 03 0 s V V Re 2 for fixed apparent contact angles exceeding 160. Posted February 01 2008 1229 AM Does anyone have suggestions for draw-down ratios for small dia 125-1 fpvc.

Draw down ratio DDR mean diameter of die gap divided by mean diameter of tubing. Draw Down Ratio is the ratio of the cross sectional area of the extruded plastic melt to the cross sectional area of the plastic in its final product form be it a tube hose or insulation on a core such as a wire or cable. The high quality of our extrusion tooling enables your company to output the highest quality product.

The calculators we provide will help you in specifying the extrusion tooling specific to your end product. After using the Draw Down Calculator below you can Request a Quotation or contact Guill to discuss how we may serve you. Profile draw-down ratio.

Draw down ratio is the ratio of the cross sectional area of the extruded plastic melt to the cross sectional area of the plastic in its final product form be it a tube hose or insulation on a core such as a wire or cable. Shawn8791 Senior Member. Maintain uniform wall thickness important.

Extrusion Parameters Parameters include die angle a extrusion speed billet temperature and lubrication Extrusion ratio R A o A f typical values of 10 to 100 Circumscribing Diameter CCD for Aluminum 6 mm to 1 m for steel up to 015 m Shape factor PerimeterCCD Extrusion constant k Typical lengths 75 m. Make walls no thicker than 4 mm. The drawdown ratio DDR characterizes a tubular die and is defined as the ratio of the cross-sectional area of the annular die to the cross-sectional area of the finished insulation as seen in Fig.

Plastic processing forums for extrusion information and advice and for other feed screw applications. Our extrusion calculator tools help you determine draw down ratio and visualize DDR from different tooling configurations convert feet per minute and pounds per hour and estimate savings and end product output when using Guill tooling. This can also be referred to as the area draw ratio ADR.

Ldpe Blown Film Waxs As A Function Of Their Draw Down Ratio And Corres Download Scientific Diagram

Tip And Die Calculator Milacron

The Effects Of Blow Up Ratio A And Draw Down Ratio B To The Download Scientific Diagram

Fundamentals Of Extrusion Technology Wire Cable India

Draw Ratio Balance Big Chemical Encyclopedia

Ldpe Blown Film Waxs As A Function Of Their Draw Down Ratio And Corres Download Scientific Diagram

0 comments

Post a Comment